We offer precision flat sheet laser cutting for creating high-quality panels, frames, signage, and architectural elements. Designed for accuracy and durability, our services are ideal for residential, commercial, and industrial applications.

Flat Sheet Laser Cutting

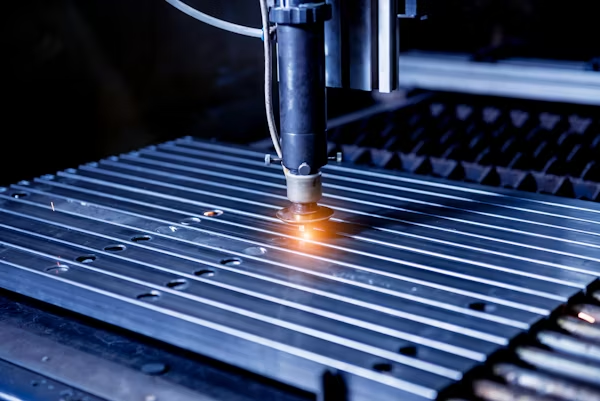

Advanced Flat Sheet Laser Cutting with LS7 Technology

Precision Flat Sheet Cutting with LS7 Technology

At RFC Corp, we leverage the advanced LT8.20 Laser Tube Cutter to deliver precision laser cutting for tubes and profiles. Our state-of-the-art laser cutting technology ensures that each part we produce meets the highest standards for accuracy and efficiency, allowing us to handle a wide variety of materials with ease.

Why Choose Our Flat Sheet Laser Services?

We deliver high-precision flat sheet laser cutting with clean edges, consistent quality, and fast turnaround. Whether for architectural panels, signage, or machine components, our service ensures accuracy, efficiency, and minimal material waste—making it a smart choice for any project.

Versatile Material Compatibility

Our laser cutting services can handle steel, aluminum, stainless steel, and other metals, allowing us to deliver versatile solutions for different applications.

Complex Designs

Whether you need to cut simple shapes or intricate patterns, the LS7 allows for complex geometries to be cut with ease, making it perfect for custom designs.

Flat Sheet Laser Cutting Process

Efficient Flat Sheet from Start to Finish

We follow a precise process—from design and material selection to fabrication and installation.

Step

01

Design Phase

We start with your design, whether it’s a CAD drawing or a conceptual idea. Our team works closely with you to ensure the design specifications are clear and meet your requirements.

Step

02

Material Selection

Depending on your needs, we choose the most suitable material for your project, from aluminum and steel to stainless steel and more.

Step

03

Laser Cutting

Our LS7 Laser Cutter takes over and cuts the material according to the design, ensuring clean, smooth edges and precision.

Step

04

Inspection

Once the cutting process is complete, we perform a thorough inspection to ensure the cuts meet the required tolerances and specifications.

Step

05

Finishing Services

If necessary, we can offer additional services such as deburring, welding, or powder coating to finish your parts.

Precision You Can Rely On

Our flat sheet laser cutting services combine accuracy, speed, and versatility. Using advanced technology, we produce custom-cut components that meet exact specifications—ideal for industries needing flawless results in every cut.

High Precision

The LS7 Laser Cutter provides exact and clean cuts, ensuring that each metal sheet is processed with high accuracy and minimal material loss.

Speed and Efficiency

The LS7 laser cutting machine operates at high speed, allowing for quick production cycles without sacrificing quality, making it ideal for large orders and high-volume runs.

Applications of Flat Sheet Laser Cutting

Our Flat Sheet services are ideal for a wide variety of industries and applications:

Architectural Metal Design

- Decorative panels & cladding

- Architectural building elements

- Residential & commercial use

Custom Laser Signage

- Business signage & logos

- Clean, high-precision cuts

- Eye-catching metal displays

Functional Metal Parts

- Machine brackets & mounts

- HVAC & construction pieces

- Grates, fences, and panels

What We Offer

- High-Speed Production: The LS7 Laser Cutter is built for fast and efficient production, allowing for quick turnaround on both small and large orders.

- Precision and Clean Edges: The advanced laser cutting technology ensures that all parts are cut to the exact specifications, with smooth edges and no need for excessive finishing or rework.

- Reduced Waste: The precise cutting capability of the LS7 minimizes material waste, making your project more cost-effective and environmentally friendly.

- Cost-Effective: Our high-efficiency flat sheet laser cutting ensures minimal material loss, making it an affordable option for all types of projects.

- Customizability: Whether you're creating a few custom components or require a high-volume order, we offer the flexibility to meet your specific needs with precise cuts.

FAQs

Frequently Asked Questions

What types of materials can you cut with the LS7 Laser Cutter?

We are equipped to cut steel, aluminum, stainless steel, and other metals with high precision. Let us know the material you’re working with, and we will confirm its compatibility.

Can you handle custom shapes and intricate designs?

Yes! The LS7 Laser Cutter is capable of cutting complex shapes and intricate patterns, so whether you have a simple or detailed design, we can accommodate it.

What is the maximum size of flat sheet material you can cut?

Our LS7 Laser Cutter can handle flat sheets up to 4’ x 8’ in size, allowing us to cut large parts or multiple smaller parts from a single sheet.

How do I know if laser cutting is right for my project?

Laser cutting is an excellent choice for high-precision, high-speed cutting of flat materials. If you need complex designs, clean cuts, or large quantities, laser cutting may be the best option.

What is the lead time for flat sheet laser cutting projects?

The lead time depends on the complexity and volume of your project. Small to medium-sized orders can usually be completed in 3-7 business days, while larger orders may take a bit longer.

Can you cut through thick materials with the LS7?

The LS7 is capable of cutting thicker materials, up to 1/2″ for steel and slightly thinner for aluminum and stainless steel. For extremely thick materials, we will guide you through the best cutting options.

Get a Quote Today!

Ready to take the next step in your project? Contact RFC Corp for a custom quote on your flat sheet laser cutting needs. We are here to provide high-precision solutions for any project, large or small.