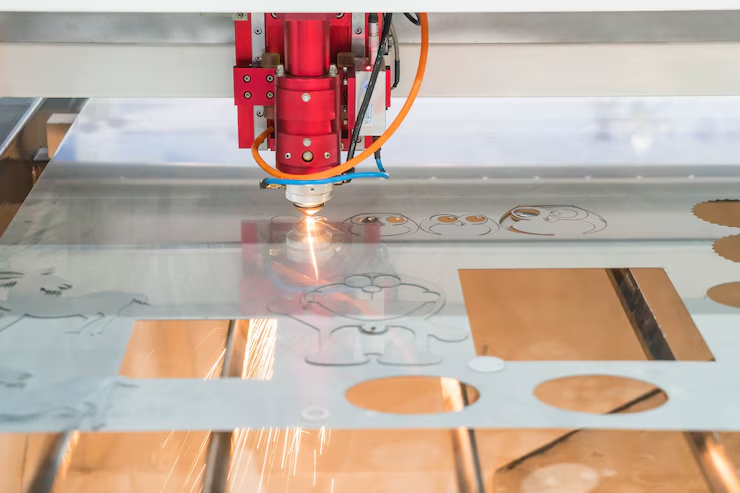

Equipped with high-speed spindles and large-format capacity, our CNC router delivers clean, accurate cuts on a variety of materials. From smooth aluminum finishes to complex shapes in wood or plastic, we ensure precision, consistency, and minimal post-processing every time

CNC Routing – Onsrud M-Series

Precision Routing for Complex Cuts, Shapes, and Finishes

High-Precision CNC Routing for Complex Designs

At RFC Corp, our CNC Routing services are performed using the advanced Onsrud M-Series router, designed for high-precision cutting of non-ferrous metals, composites, and plastics. This versatile machine allows us to craft complex geometries, custom signage, architectural elements, and detailed panel work—all with exceptional accuracy and smooth finishes.

Why Choose CNC Routing at RFC Corp?

Our CNC routing delivers high-precision results for complex shapes and fine details across various materials.

Superior Edge Quality

The Onsrud router delivers smooth edges ideal for visual or exposed surfaces.

Versatility in Design

Easily create pockets, slots, countersinks, or 3D elements with precision.

Our Routing Process

How We Shape with CNC Precision

We use advanced routing to deliver clean, accurate cuts for custom panels, signs, and components.

Step

01

Design Submission

Send your DXF, DWG, or vector artwork—or let our team assist you with creating one.

Step

02

Material Selection

Choose from our in-stock aluminum sheets or bring your own material.

Step

03

Precision Routing

We route the exact shapes, sizes, and depths required for your design.

Step

04

Finishing Touches

We deburr, polish, and prepare your parts for delivery or assembly.

Precision Routing for Complex Creations

From custom signage to intricate architectural features, our CNC routing ensures accuracy, smooth edges, and professional results—ideal for both small runs and large-scale projects.

Fast Turnaround

Great for both one-off prototypes and full-scale production runs.

Custom Finishing Options

Combine routing with welding, powder coating, or laser cutting for complete fabrication solutions.

Key Features of Our CNC Routing Services

- High-Speed Spindle: Allows for smooth, burr-free cuts on aluminum and other soft metals with tight tolerances.

- Large Format Capability: Ideal for oversized panels, signage, architectural components, and high-volume batch work.

- Precision Control: The Onsrud M-Series ensures repeatability for intricate designs, curves, beveled edges, and compound cuts.

- Clean Finish with Minimal Post-Processing: Our routing produces clean edges that reduce the need for additional sanding or deburring.

- Multi-Material Compatibility: Beyond metal, we can route plastics, composites, ACM, PVC, and wood products when required.

Versatile Applications of CNC Routing

Our CNC routing services support a wide range of applications—from aluminum panels and custom signage to enclosures and architectural features. Whether for design, function, or branding, we deliver clean, precise cuts tailored to your specific needs.

- Aluminum Panels & Cladding: Architectural façades, interior design features, and decorative wall elements.

- Custom Signage: CNC-routed logos, 3D lettering, and branded displays with professional finishes.

- Precision Enclosures: Custom-cut enclosures or mounts for electrical and mechanical systems.

- Architectural Components: Laser-precise decorative screens, lattices, and perforated panels.

- Furniture & Fixtures: Brackets, panels, and structures for retail, residential, or industrial use.

FAQs

Frequently Asked Questions

What makes CNC routing different from laser cutting?

Laser cutting uses heat to vaporize material, while CNC routing uses a spinning tool to carve and cut. Routing is often better for thicker, softer metals and where smoother edges are needed.

Can you route multiple materials in one job?

Yes, if your design calls for mixed materials like ACM and aluminum, we can accommodate with tool changes.

How thick can the Onsrud M-Series cut?

We routinely route aluminum up to 1/4″ thick, and other materials up to 1” thick depending on density.

Do I need to provide CAD files?

It helps to have DXF or vector files, but if you only have a sketch or concept, our team can help convert it into a machinable format.

What finishes do you offer after routing?

We can deburr, polish, or finish parts with powder coating, anodizing (via partner), or welding based on your needs.

Ready to Bring Your Vision to Life?

From detailed signs to architectural metalwork, RFC Corp’s CNC Routing service combines cutting-edge technology and hands-on craftsmanship. If precision, speed, and high-end finishes matter, you’re in the right place.